Dr. Robert | Spesialis Teknologi Tinta Senior | 18 Tahun Pengalaman Industri

Poin-poin Utama: Tinta gravure dan fleksografi adalah dua jenis tinta utama dalam industri percetakan, masing-masing memiliki karakteristik dan aplikasi yang unik. Tinta gravure dikenal karena saturasinya yang tinggi dan efek cetak yang halus, sementara tinta fleksografi disukai karena ramah lingkungan dan adaptabilitasnya yang luas. Pemilihan tinta yang tepat sangat penting untuk kualitas cetak dan pengendalian biaya.

Tinta gravure, juga dikenal sebagai tinta intaglio, adalah jenis tinta yang dirancang khusus untuk pencetakan gravure. Tinta ini bekerja dengan mengisi area gambar tersembunyi pada pelat cetak dengan tinta, mengikis tinta dari area non-gambar, dan akhirnya mentransfer gambar ke substrat melalui tekanan.

Tinta gravure dapat diklasifikasikan berdasarkan metode pembuatan pelat, karakteristik tinta, dan jenis mesin cetak:

· Dengan Metode Pembuatan Plat: Tinta gravure foto, tinta gravure terukir

· Berdasarkan Karakteristik Tinta: Tinta gravure berbasis air, Tinta gravure berbasis alkohol, Tinta gravure berbasis benzena, Tinta film plastik

· Berdasarkan Jenis Mesin Cetak: Tinta gravure alas datar, Tinta gravure putar

Mesin Tinta Gravure (Tinta Mutiara dengan pigmen Mutiara Emas)

Formulasi tinta gravure biasanya mengandung komponen-komponen berikut: Resin (35%-40%), Pigmen (8%-16%), Pengisi (2%-5%), Pelarut (30%-35%), dan Aditif (10%-20%).

Pelarut umum meliputi pelarut alkohol (etanol, isopropanol), pelarut ester (etil asetat, butil asetat), pelarut benzena (toluena, xilena), dan pelarut keton (sikloheksanon, butanon).

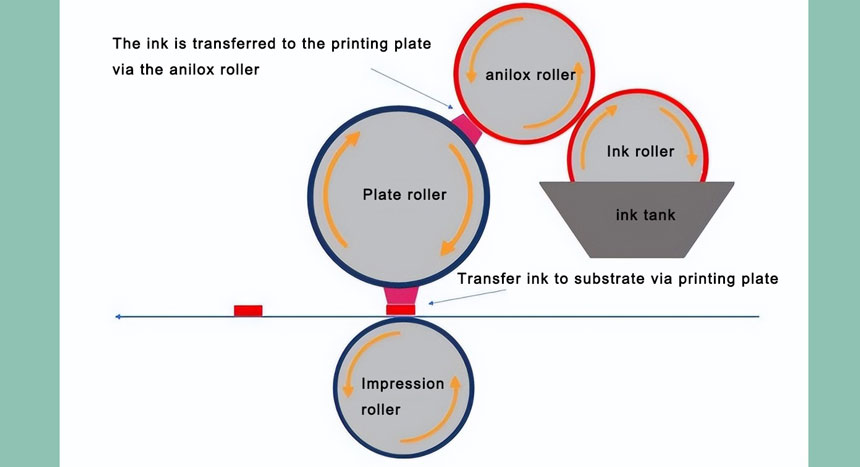

Tinta fleksografi awalnya disebut "tinta anilin" dan kemudian berganti nama menjadi "tinta fleksografi". tinta cetak Karakteristiknya meliputi viskositas rendah, cepat kering, dan sifat lingkungan yang sangat baik.

Tinta fleksografi diklasifikasikan berdasarkan jenis pelarut:

· Tinta Fleksografi Berbasis Pelarut: Cocok untuk bahan yang tidak menyerap seperti film plastik dan foil logam

· Tinta Fleksografi Berbasis Air: Cocok untuk bahan penyerap seperti kertas dan karton, ramah lingkungan dan aman

Formulasi tinta fleksografi biasanya meliputi: resin , pigmen , pelarut , Dan aditif Mekanisme pengeringan meliputi pengeringan penguapan, pengeringan penetrasi, dan penyembuhan reaktif.

Metode pencetakan tinta fleksografi

|

Aspek Perbandingan |

Tinta Gravure |

Tinta Fleksografi |

|

Prinsip Pencetakan |

Transfer gambar melalui tinta yang disimpan di ceruk pelat |

Transfer tinta melalui pelat fleksibel dan rol aniloks |

|

Viskositas Tinta |

Viskositas lebih tinggi, cocok untuk pencetakan halus |

Viskositas lebih rendah, cocok untuk pencetakan kecepatan tinggi |

|

Substrat yang Cocok |

Kertas, film plastik, foil logam |

Kertas, karton, film plastik |

|

Presisi Pencetakan |

Presisi tinggi, cocok untuk pola halus |

Presisi sedang, cocok untuk area padat yang besar |

|

Metode Pengeringan |

Terutama penguapan pelarut |

Kombinasi penguapan, penetrasi, dan penyembuhan reaktif |

|

Dampak Lingkungan |

Jenis tinta tradisional memiliki masalah lingkungan; tinta berbasis air dan bebas benzena yang baru semakin membaik |

Tinta berbasis air memiliki sifat lingkungan yang sangat baik |

|

Kecepatan Pencetakan |

Pencetakan berkecepatan tinggi, hingga 150 m/menit |

Pencetakan berkecepatan tinggi dengan kemampuan beradaptasi yang baik |

|

Faktor Biaya |

Biaya pelat lebih tinggi, cocok untuk cetakan dalam jumlah besar |

Biaya plat lebih rendah, cocok untuk cetakan pendek hingga sedang |

Rekomendasi Ahli: Saat memilih jenis tinta, pertimbangkan substrat cetak, kecepatan cetak, persyaratan presisi, standar lingkungan, dan keterbatasan anggaran. Untuk kebutuhan pencetakan presisi tinggi dan jangka panjang, tinta gravure lebih disukai; untuk aplikasi yang membutuhkan standar lingkungan dan kemampuan adaptasi yang tinggi, tinta fleksografi memiliki keunggulan.

· Seri Pigmen Pearlescent ( Pigmen mutiara putih keperakan , pigmen mutiara kilau emas, pigmen mutiara berwarna, dan seri lainnya)

· Bahan Glitter & Berkilau

· Pigmen Organik

· Pigmen Fluoresens

· Bubuk Reflektif

· Pigmen Aluminium

· Pigmen Bunglon

· Stabilisator UV & Penyerap UV

· Resin CPP

· Resin Poliamida

· Resin CEVA

· Resin PVB

· Pengikat Tinta Lainnya

· Seri Perekat

· Pencetakan presisi tinggi (kemasan rokok, gambar)

· Kemasan fleksibel dan kemasan komposit

· Aplikasi yang memerlukan efek visual khusus (mutiara, metalik)

· Cetakan dalam jumlah banyak dengan volume tinggi

· Area padat besar dan pencetakan teks (label, karton)

· Kemasan makanan dan pencetakan publikasi

· Aplikasi dengan persyaratan lingkungan yang tinggi

· Cetakan dalam jumlah kecil hingga sedang yang membutuhkan fleksibilitas

Dengan meningkatnya kesadaran lingkungan dan kemajuan teknologi, tinta gravure dan fleksografi berkembang menuju solusi yang lebih ramah lingkungan dan berkinerja lebih tinggi:

· Keberlanjutan Lingkungan: Tinta berbasis air dan bebas benzena menjadi arus utama, mengurangi emisi VOC

· Kinerja Tinggi: Mengembangkan formulasi tinta untuk kecepatan cetak yang lebih tinggi dan kualitas cetak yang lebih baik

· Tinta Fungsional: Meningkatnya permintaan tinta dengan fungsi khusus (anti-pemalsuan, antibakteri)

· Standardisasi: Peningkatan proporsi tinta universal untuk mengurangi tekanan inventaris printer

Institut Teknologi Bahan Percetakan 2025 | Artikel ini hanya untuk referensi; konsultasikan dengan teknisi profesional untuk aplikasi spesifik